- Designed for prolonged blasting by two, four or even six independent operators together without extra abrasive loading.

- Safe and efficient due to high volume of abrasive media what allows to save time on extra loading and carry out large areas blasting.

- Capacity optimized for 840 kPa operating pressure with compressor delivery rate 16 to 48 m3 per min. depending on number of abrasive metering valves connected.

- Available in fixed and mobile versions.

- Each operator station has pneumatic (with hose lengths up to 40 m) or electrical (hose lengths over 40 m) Remcon® remote control panel which allows each operator start and stop blasting independently.

- Equipped with Sandsturm®-P pneumatic abrasive metering valve designed for up to 4 mm grade media. Has a 50 liter moisture separator which completely removes oil and moisture from compressed air supplied to pressure tank.

- As standard machine equipped with automatic shut-off valve.

- Loading bulk is safely closed all time when machine is pressurized and protected from water and debris penetration with rubber seal cover.

- At construction site mobile version can easily and fast travel around with torsion suspension chassis, brakes, tail stop and turn signals.

AREA OF APPLICATION

Can be used for motorway and rail bridges repair and construction, at refinery, tank farms, shipbuilding and repairing yards.

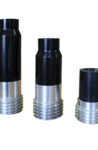

ABRASIVE MEDIA

Supplied with Sandsturm® multipurpose abrasive metering valves, which allow working with any common abrasives 0,1 to 4,0 mm grade: cast-iron and steel shot and grit, marble and granite chips, glass beads, aluminum oxide, silicon carbide, alundum, copper and nickel slag and other kinds of media fabricated specially for blasting.

- Вы можете получить оборудование путем самовывоза с нашего склада, находящегося по адресу: г. Санкт-Петербург, ул. Предпортовая д. 6.

- Наша компания осуществляет бесплатную доставку до терминала любой выбранной Вами транспортной компании.

- Доставка осуществляется во все регионы России.