Designed for long-term abrasive blasting works without additional loading of abrasive. As standard, it allows you to clean the surface of up to 70 m2 on a single load. It is provided with a supply line of 2 inches and a receiver for smoothing of incoming compressed air ripples. Two pneumatic metering units of SANDSTURM®-P abrasive allow two operators to treat the surface at the same time; the first operator can treat the surface and the second one can blow dust particles from the surface without the abrasive supplied.

AREA OF APPLICATION

Used at industrial facilities with a large amount of work:

- shipbuilding and ship repair yards

- repair and construction of roads and railway bridges

- oil and gas storage facilities

- to remove oil, lubricants, old paint, scale, dirt, corrosion products and other foreign substances, creating perfect surface for applying protective anti-corrosion coating

ABRASIVE MEDIA

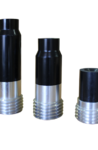

Supplied with Sandsturm® multipurpose abrasive metering valves, which allow working with any common abrasives 0,1 to 4,0 mm grade: cast-iron and steel shot and grit, marble and granite chips, glass beads, aluminum oxide, silicon carbide, alundum, copper and nickel slag and other kinds of media fabricated specially for blasting.

Its work is performed by means of introduction of abrasive material through the abrasive metering valve SANDSTURM®-P and compressed air through the air line into a pusher line assembly.

After mixing in the adjusted proportion abrasive-air mixture is supplied to the abrasive blasting hose at high pressure and is directed on to the surface that is being treated, passing through the abrasive blast nozzle and speeding up.

- Все пескоструйные аппараты Blastcor® - BM сертифицированы на соответствие техническому регламенту Таможенного Союза ТР ТС.

- Регистрационный номер декларации о соответствии ТС № RU Д-RU.АВ45.В.36364

- Вы можете получить оборудование путем самовывоза с нашего склада, находящегося по адресу: г. Санкт-Петербург, ул. Предпортовая д. 6.

- Наша компания осуществляет бесплатную доставку до терминала любой выбранной Вами транспортной компании.

- Доставка осуществляется во все регионы России.